“The more beautifully and skillfully something I make, the more people think it was done with a laser cutter,” said a Kude craft artisan.

It provoked me to question:

- Is only a good appearance all that really matters?

- If the final result looks similar, does the latest technology, which allows for inexpensive mass production, really better?

Through this article, I want to explore why Kude craft, a traditional heritage craft from Kagawa (Shikoku, Japan), continues to thrive despite the rise of laser cutting technology by comparing the characteristics of both methods through this article.

I’m Satoko Kamada, the founder of KoLe SHIKOKU Japan and a Bespoke Artisanal Experience Coordinator. I work closely with heritage craft artisans in Shikoku, Japan, to cater to tailored experiences. One of the many services I offer includes coordinating artisan-made or artisan-collaborative product developments for product designers and producers worldwide.

Here’s what you can expect to learn as we dive deeper into this topic:

- What is Kude Craft?

- Artisanal Dilemma—”The more beautifully and skillfully something I make, the more people think it was done with a laser cutter,”

- Laser Cut V.S. Kude Craft

What is Kude Craft?

Before we discuss the topic, I would like to explain the Kude Craft so that we are all on the same page.

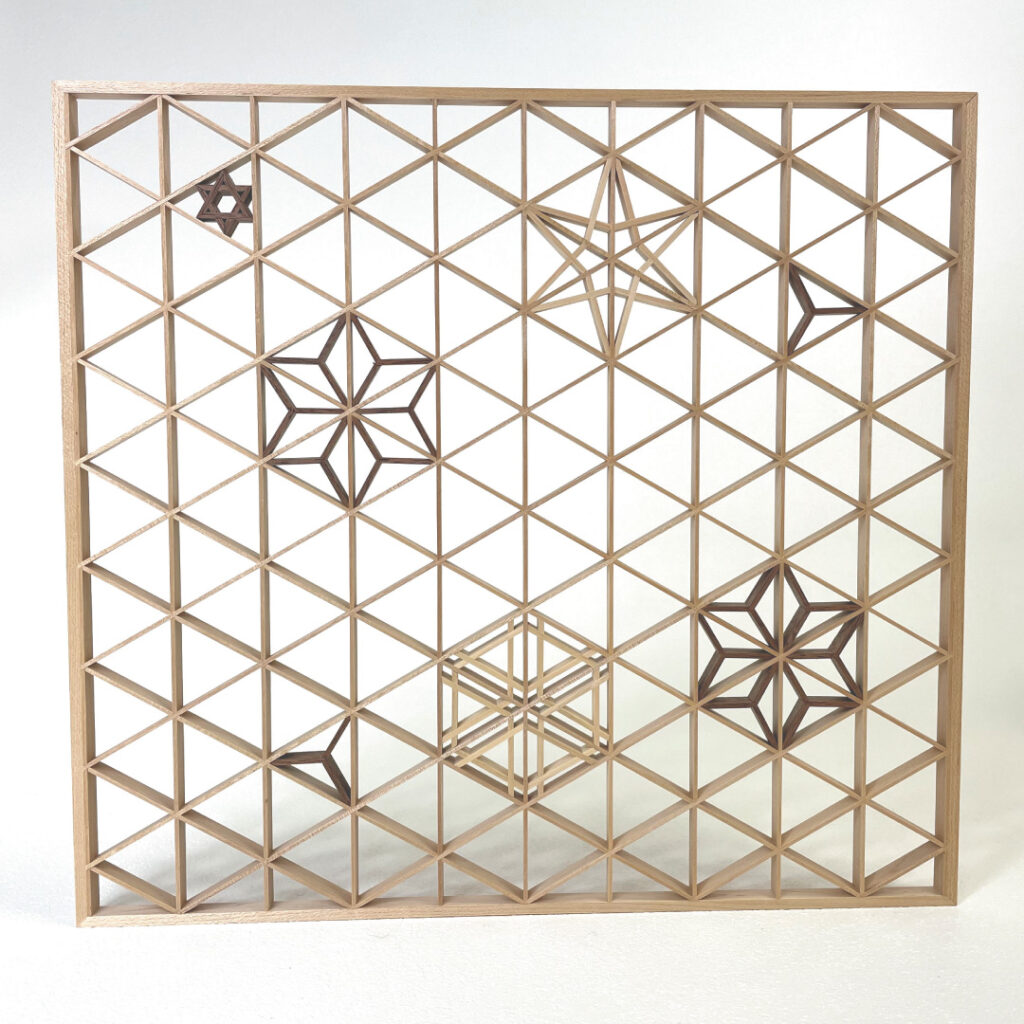

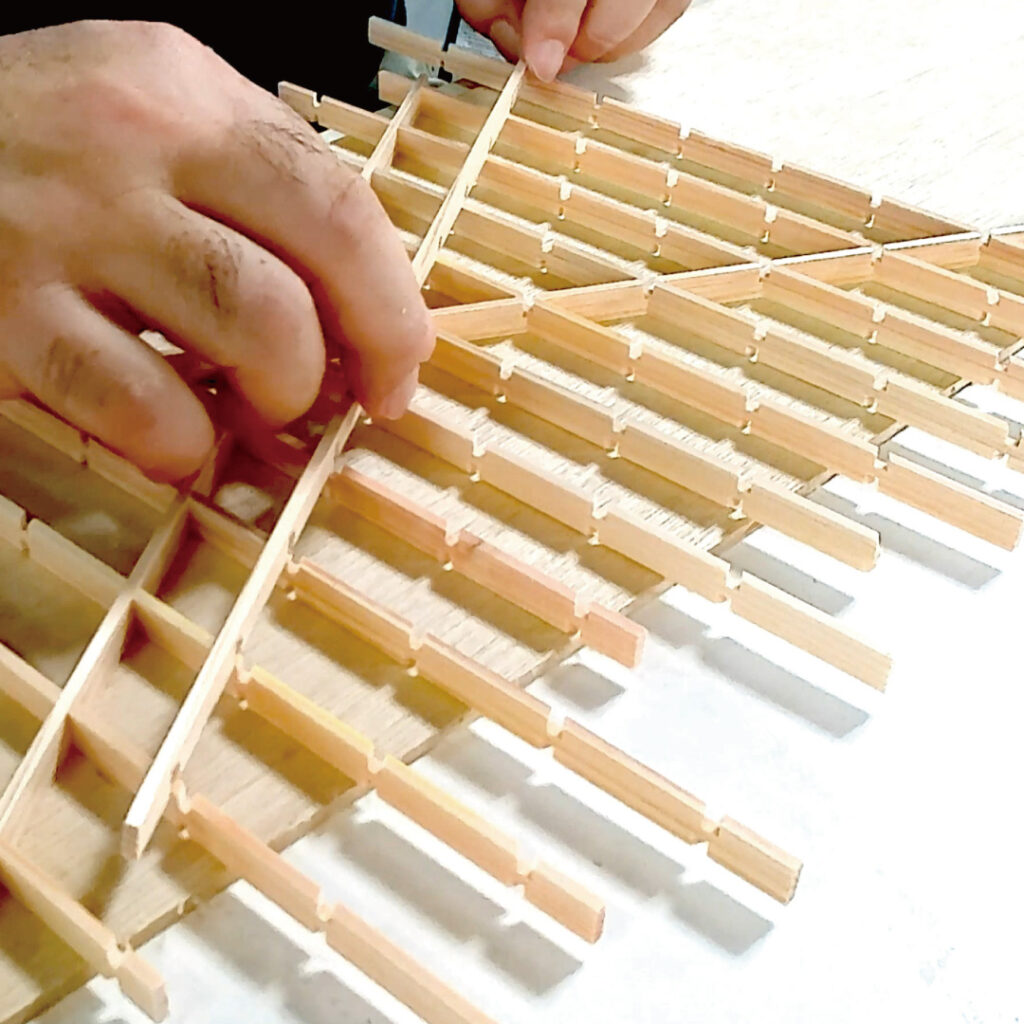

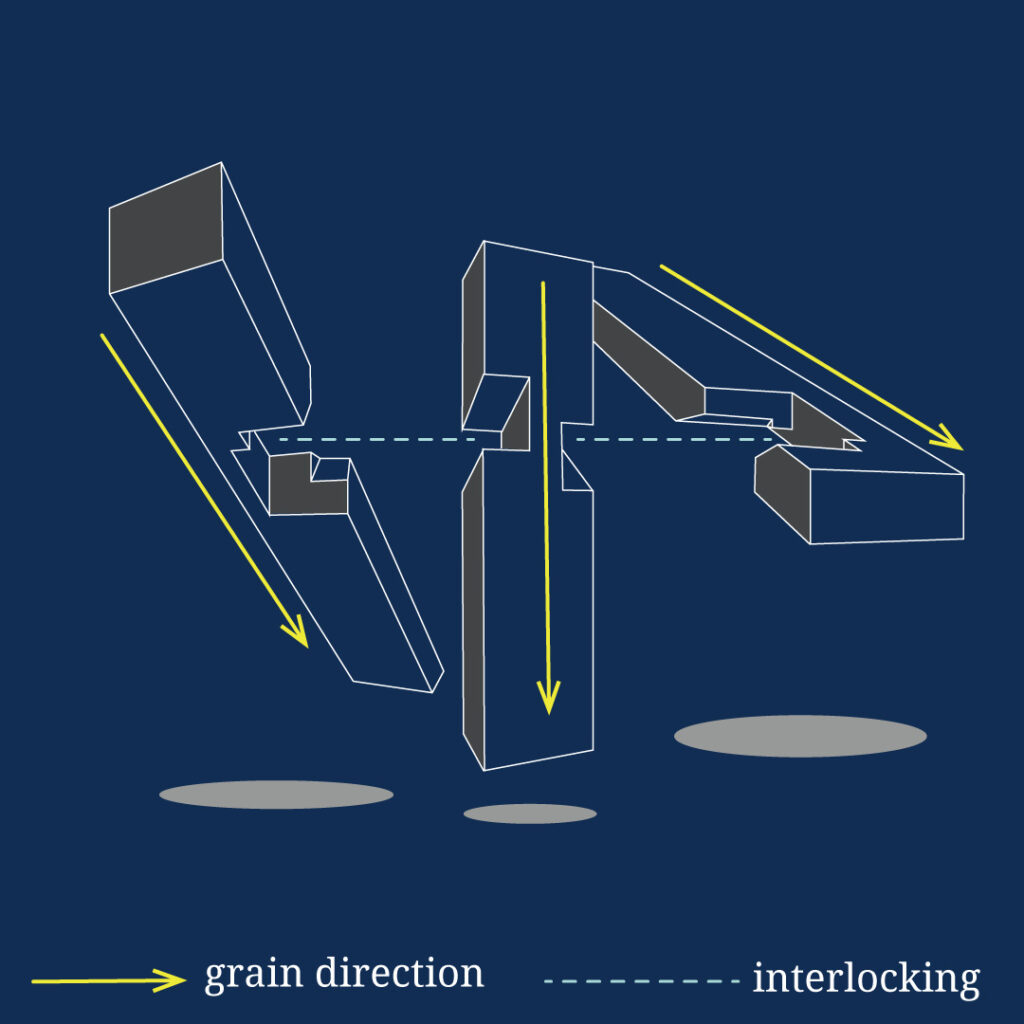

Kude Craft is a traditional Japanese craft in which artisans meticulously piece together small, delicately shaped strips of wood into intricate geometric patterns. Each piece is shaped to interlock with others without the use of nails or glue. Seen in sliding doors, screens, and other decorative elements, Kumiko reflects centuries of refined precision and craftsmanship.

You might have heard of this craft before; in other parts of Japan, it is known as “Kumiko (組子).” In Kagawa prefecture, the same craft is called “Ku-de(組手).” So, despite the damage to my blog’s SEO, I proudly use our local term for this craft: Kude.

Since we all know what a Kude craft is, I can now share an anecdote about witnessing our collaborating Kude artisan being annoyed by something for the first time.

Artisanal Dilemma—”The more beautifully and skillfully something I make, the more people think it was done with a laser cutter.”

It happened when Mr. Morimoto, our collaborating Kude artisan, and I participated in a trade show in Tokyo in 2020. The booth was for Mr. Morimoto’s studio, and I was there as an assistant. He displayed both traditional and aspiring modern items at the booth. Over those three days, we heard the same comment a few times from different people.

Every time he hears the comment, I feel Mr. Morimoto is significantly annoyed, and he tries to hold it back rather than express it. He is usually very low-tempered but warm and welcoming. But to be fair, I was more offended by and furious about the comment than Mr. Morimoto. Can you guess the comment that kept rubbing us the wrong way?

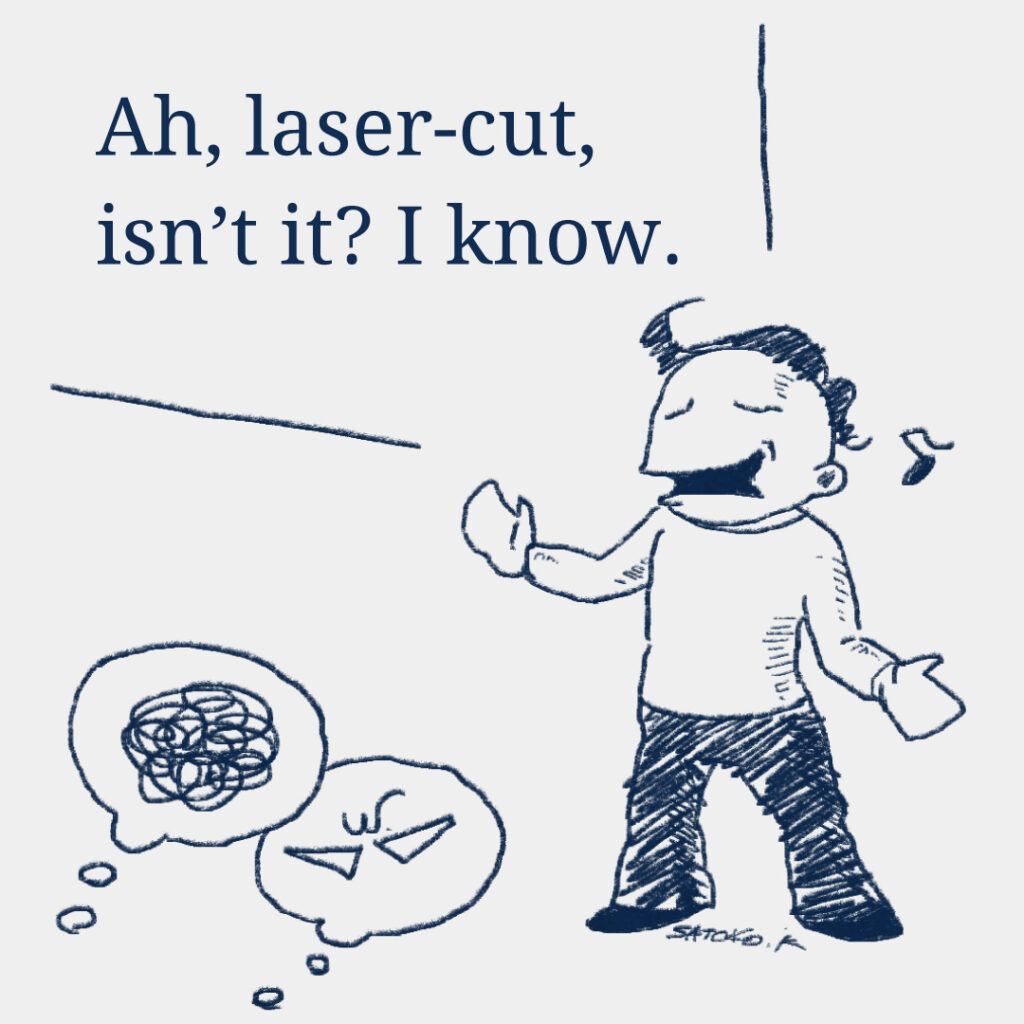

This kept happening to us at the trade show. A person leans over the Kude product, observes it for a few seconds, and says:

“Ah, laser-cut, isn’t it? I know (as if there is nothing special about it and bored by it).”

While Mr. Morimoto replied, “It’s hand-cut and hand-assembled,” very calmly yet a little bit coldly, I clenched both of my fists tightly and took a deep breath. What was a relief, even in such a situation, was that once they realized it was not a laser-cut pattern but the artisan’s handwork, they expressed awe and apologized to Mr. Morimoto.

It was sad to realize that many Japanese people today cannot recognize Kude/Kumiko crafts by looking at them. I will explain this later, but if you are surrounded by natural wood products, not fake wood texture-printed ones, you can tell by looking at them. I remember Mr. Morimoto and I looking at each other, saying, “Are laser-cut products our competition in the 21st century?”

Since then, “Ah, laser-cut, right? I have a small machine to do it at home, too.” has happened once in a couple of years.

Now, we have a problem to solve.

It is not their fault that they don’t know the heritage craft. It is our problem to solve: “What can we do to avoid being mistaken as laser-cut products?”

On several occasions, during discussions regarding the “Laser Problem,” Mr. Morimoto said, “The more beautifully and skillfully something I make, the more people think it was done with a laser cutter. I can make it smooth, but is it better to keep it a bit rough so that customers and anyone who sees it can see it is hand-assembled?”

What a conundrum and dilemma!—The current situation is making an artisan of precision consider creating something (in his world) less of his ability!?

Can you solve this? If you can, let me know. I will discuss the differences between laser-cut and Kude crafts.

Laser Cut V.S. Kude Craft

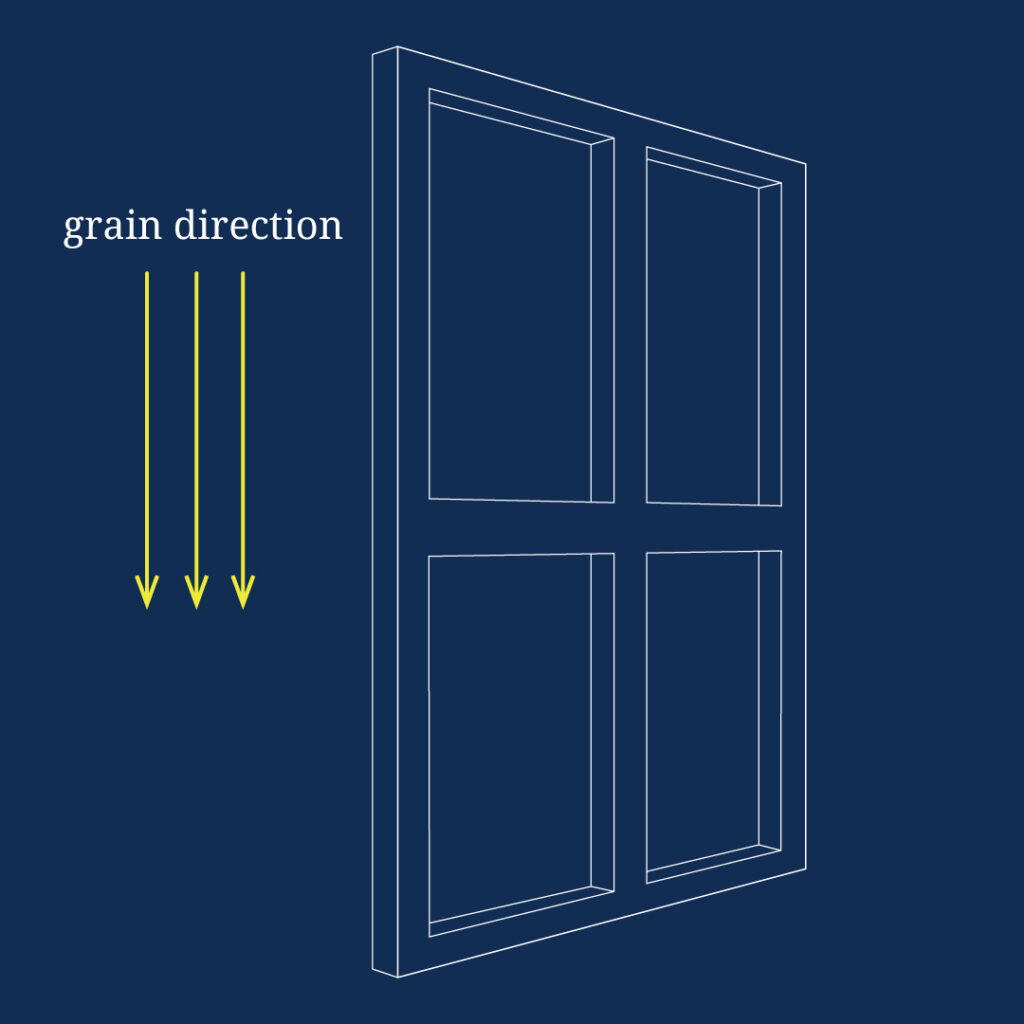

Laser-cut designs involve cutting out patterns from wooden boards using a laser. This method produces detailed and uniform patterns but can sometimes weaken the wood in the cut-out areas, making it more susceptible to damage over time.

In contrast, Kude crafts are created by hand-cutting and assembling small pieces of wood, each shaped to interlock with others. This technique provides exceptional strength and durability, as the interlocking pieces and varied wood grain directions contribute to the item’s resilience.

While laser-cut items might look similar to Kude crafts, they lack the robustness of Kude crafts. The traditional method of Kude craftsmanship not only provides a beautiful finish but also ensures the item is resilient and long-lasting.

There is more to it, but I will leave it there for now.

If you would like to know more, let me know (in the comment where this article is shared or via the contact form on our website).

Is only a good appearance all that really matters?

Now, let’s revisit the very first question.

What do you think?

I don’t think laser cutting is wrong, even when used to create Kude crafts-like designs. It’s fast, accurate, and often inexpensive, and the technology can be applied to many different materials.

But we must carefully consider its use when cutting out a wood board to recreate the Kude-craft feel. How long does it need to last? How strong does it have to be? Will it be placed in an environment where it might be frequently damaged? If it breaks too often and requires frequent reproduction, the cost might end up being comparable to having a Kude artisan create it from the start.

Today, through Mr. Morimoto’s artisanal dilemma, I’ve introduced you to a practical side of heritage crafts. The demand for Kude craft has declined compared to fifty years ago. However, craftsmanship persists, partly due to its practicality. The market may be shrinking, perhaps because many are unaware of this aspect of Kude craft.

Now that you know what Kude is and its practical aspects, how could Kude craftsmanship be used in both small and large everyday items? If you have any ideas, please let me know!

Dear product designers, producers, and other craftspeople,

You don’t need to master Kude craftsmanship yourself. Our collaborating artisan will handle the Kude part for you. So, if you have any ideas for collaboration on whole items or parts of items, don’t hesitate to contact me before dismissing your idea!

Contact:

Thank you for reading to the end. If you liked this article, please follow me wherever you find it. See you next time!

YouTube Podcast Series “The Prototypes—The Real Stories of How Artisan-made Products Were Born”

Comments by satoko